Larger companies traditionally had their own cutting departments, in which their in-house team would cut and engrave any materials they needed. The labour intensive and manual nature of these tasks meant that this was a time consuming and costly process. Designers, makers and smaller companies were unable to easily access these services due to the costs involved and not having their own in-house services.

As technology entered the design and fabrication industry, computer-controlled machines took over much of the work and a new era was born. With this, came the boom in laser cutting, particularly in the last decade. Specialist companies formed who concentrate solely on offering these services to any companies or individuals who need a cost-effective cutting service. Larger companies are now outsourcing their work to these companies and individuals and smaller companies now finally have affordable access to these services.

Laser cutting is a popular choice due to its quality finishes and the intricate design possibilities. It allows for fast turnaround times and is an incredibly versatile method of cutting and engraving materials. The accuracy and precision involved cannot be replicated by traditional manual methods, especially on multiple copies of the same item.

Let’s take a deeper look into what laser cutting services can offer.

Laser Cutting – the Basics

In some ways, the term ‘laser cutting’ is pretty self-explanatory. However, there’s a lot more to it than some might think. It’s a method that’s growing in popularity and it’s not just the design and manufacturing industry that’s taking notice. Other industries are seeing how these popular and cost-effective methods can work for them.

How it works is something of an automated process. Our laser cutting technicians need a design file in one of the following formats: .dxf, .dwg, .ai, .eps or a .pdf can be used as long as a vector can be exported from them. 3D design files are also possible to process (but it’s wise to talk to our laser cutting team about these). The vector-based files enable the computers to take the design file and translate it into a set of coordinates for the chosen material to be cut or engraved with.

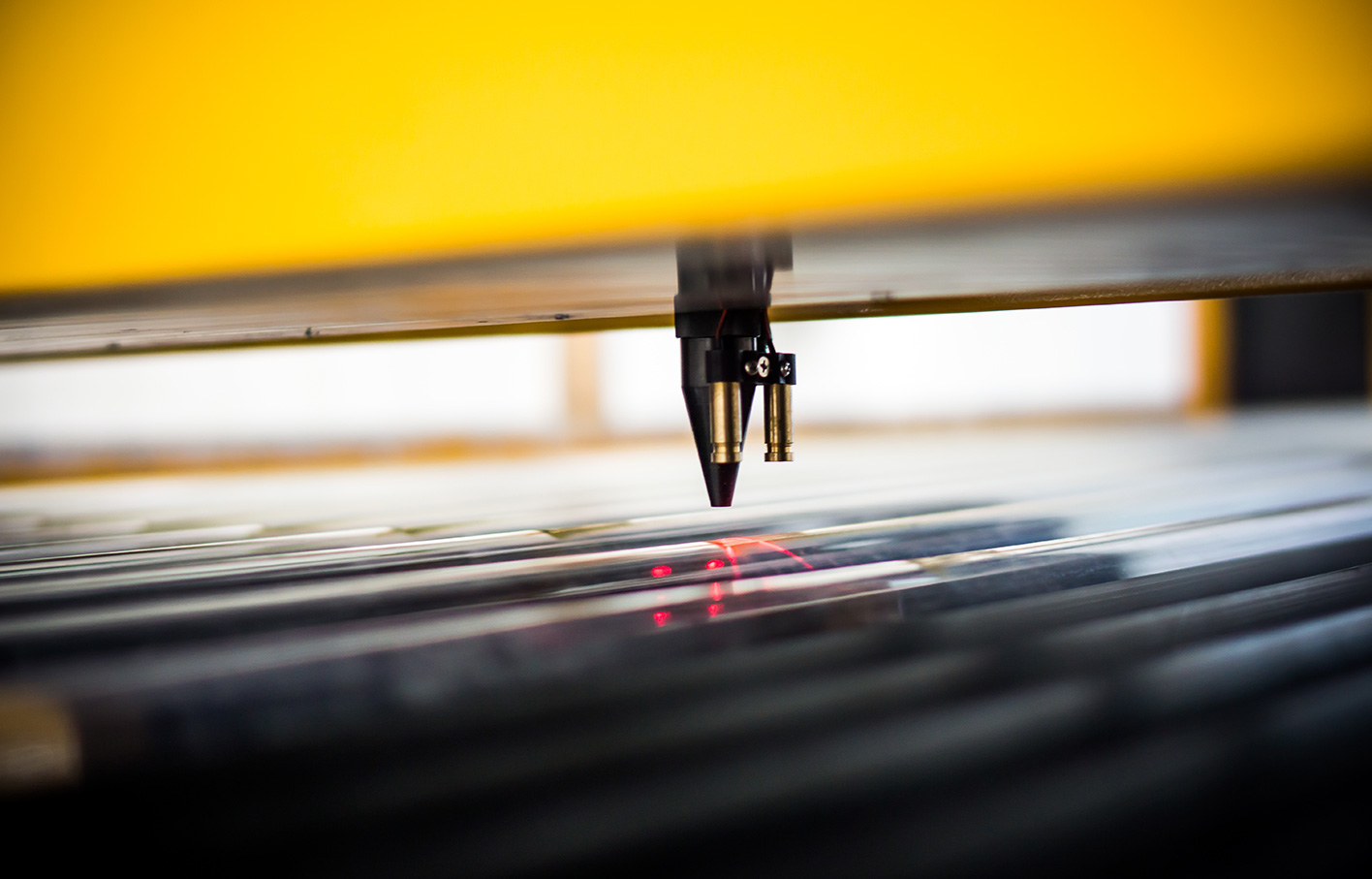

The machine’s laser beam is then sent down an encased tube by a bulb and reflected onto a series of mirrors. This then angles the beam down onto the material being cut. The laser cutting machine technician can alter the power and intensity of the laser to find the optimum level for the job. Once completed, the finished effect is smooth and of a really high quality.

What Can Laser Cutting Be Used For?

Laser cutting techniques can be used on a range of materials. Laser cutting machines are equipped with various bulbs and fire settings. Lower power settings are often used for tasks such as laser-etching wood and higher settings are used for thicker materials.

The main service accessed is cutting services but laser cut engraving services are also increasing in popularity. Examples of the materials that can be used are listed below.

Cutting:

- Plywood

- MDF

- Oak panels

- Valchromat

- Softwood

- Acrylics

- Plastics

- All laminate types

- Foam

- Card

- Soft leather

There is usually no limit on how thin the material can be in order to cut it, but the maximum thickness is usually around 24mm. As a general rule however, the thicker the material, the higher the price.

Plywood is one of the most popular material options as it’s much more affordable than solid timbers are. It has many qualities including a strong yet lightweight nature, making this sheet material one of the most regularly used for laser cutting.

Engraving:

Engraving services can include text, logos and photos onto your components or products. This is becoming increasingly popular as companies look for cost-effective ways to advertise their brand and display products.

One thing to remember when specifying laser cutting service is that laser cutting techniques usually leave a ‘blackened’ edge where they have cut any natural materials. These edges can be easily sanded back however, and our workshop team will be happy to do this for you. You should mention this when getting any costings from our laser cutting team.

What Are the Benefits of Laser Cutting?

Laser cutting has revolutionised the way material cutting projects are completed. There are many reasons for it growing in popularity as its benefits are easy to see. Let’s take a look at what some of these are:

VERSATILITY

Laser cutting projects often vary from one to the next, but the machines can cut almost anything drawn in a vector based design file. This includes:

- Sharp angles

- Smooth curves

- Small screw holes

- Complex lace designs

- Engraving of: text, logos, photos

Laser cutting is an incredible flexible technique and the machines are able to cut materials that’s not possible with CNC cutters. The lists of projects laser cutters are able to complete is endless and this has opened the doors for so many companies to have their material cut by specialist laser cutting machines.

HIGH QUALITY

Because the laser cutter’s head is smaller than that of CNC machines (computer numerical control machines that use bit tools to cut materials rather than lasers), a much sharper finish is created. This includes sharp internal corners and because the laser burns through the material rather than physically cutting it, you don’t get as much dust produced. The clean up is therefore minimal. There is also very little risk of damage to the part being cut due to no moving part ever touching the material on the machine bed. The finished effect is of high quality. It’s also true that with traditional methods, the cutting tools wear down, through their continuous use. This leads to a decrease in accuracy and quality. This is no issue with laser cutters which remain the same regardless of the amount they’re used.

ACCURACY

The small size of the laser cutter’s head ensures the cut never exceeds the width of the laser beam. This allows intricate cutting and engraving to be carried out with precision that would never be possible using tools. Any changes are also possible at just the click of a few buttons with the machines being able to adapt to these to ensure the cutting is as accurate as possible.

SPEED

Due to the automated nature of laser cutting, the speed at which the job is completed is fantastic. Once the design file is loaded onto the laser cutting machines, the process is automated from then on. Materials do not need fixing down as the only thing touching the material on the machine bed is the laser beam. This ensures the material is cut or engraved without any wobble, leading to a fast and efficient turnaround time. Various materials and thicknesses can all be cut within one operation without manual intervention, speeding up the process considerably.

REDUCED COST

The largely automated laser cutting process has not only reduced the number of people needed to complete the job but also the time required by those technicians who are required to interact with the laser cutting machines. Experts technicians are able to set up jobs quickly and efficiently using the design files and then after this, the laser cutting machine does the hard work for them. The quick and efficient process has resulted in laser cutting services becoming a cost-effective way of cutting or engraving materials. Larger companies are now choosing to outsource to laser cutting companies and the services are accessible to everyone.

How Can We Help You?

If you have a laser cutting project, you need a company who are the experts at what they do. The expert company should have the specialist staff, the right equipment, and the right experience to successfully deliver high quality products. Here, at Aldworth James & Bond, we have years of experience and deliver a high quality and cost-effective service that has more than exceeded our customer’s expectations.

At Aldworth James & Bond, we offer a range of digital fabrication services, including CNC and laser cutting. The laser cutting London service we offer is fast and cost- effective meaning that you will get the best deal for your project. Our central London (zone 2) location enables us to deliver to any location, or you can collect your items from us if required.

Our laser cutters have a standard sheet size of 2440 x 1220mm, meaning we can cut any sized material from A4 upwards to a full sheet size. Our laser cutters can easily cut smaller sized pieces.

Health and safety is extremely important as part of working practices. Our 150W bulb is very powerful, but it’s always operated in a controlled and safe environment.

Our Experts—

Our specialist team have years of experience between them in design and manufacturing fields, so you’re in safe hands. We have experience in many complex projects, including architectural models, signage and furniture projects. All of our staff are from a design or manufacturing background so have the knowledge to deliver an exceptional service.

Collaborative Working—

Our expert team is happy to help you with any design solutions you may need. We understand that every project is unique, even if it’s just a simple cutting job. We are happy to work as closely with you as you like. Whatever stage your project is at, we can provide you with any advice you may require. This includes help with:

- Method of cutting

- Design files

- 3D design advice

- Material choices

- Lead times

- Quotes and costings

- Booking your job in with our machine technicians

We encourage customers to access pre-cutting advice available to them as it helps to eliminate mistakes and in turn, reduce turnaround times and costs.

Our Promise—

Customer service is at the heart of what we do and we believe in creating a service that puts the customer at the centre and delivering the high quality products you deserve. We promise to provide:

- A laser cutting London based service – but we can deliver to any location

- Any pre-cutting advice you may want

- Help for any design solutions needed

- Fast turnaround times, especially if we have the material already in stock

- The packing and labelling of your finished items so that you can keep track of what has been delivered

- Speedy delivery of finished items

- Fast turnaround times for any costings

- An easy payment system (including credit cards)

Summary

The design and manufacturing industry has come a long way in the past few decades. Traditional manual methods were labour intensive and therefore not as cost-effective, making the services inaccessible to many individuals and smaller companies.

The boom of technology revolutionised the industry, with computer-controlled machines now being able to accurately and quickly cut a large range of materials. With this advancement, also came laser cutting. This involves cutting materials with a laser that has translated coordinates from a design file. This cost-effective method is versatile, reliable, accurate, fast and produces high quality finishes.

Aldworth James & Bond has a specialist laser cutting London team who can help you to make your cutting project a success. However large or small your job, we are happy to help. We have an expert team on hand who have years of experience in the field and are happy to advise you as much as you require. We offer laser cutting and engraving services and are based in a central London location (Zone 2). You are welcome to collect your finished items, or we can deliver to any UK location, just ask.

Next Steps

To speak to one of our team about the laser cutting you are thinking about, please choose one of the contact methods listed below. One of our expert technicians can discuss your requirements with you and let you know how our laser cutting services can help you. Even if you just need a quote, an informal chat, detailed advice, or to book your job in with our team, we would love to hear from you.