Wood cutting has been carried out for years. Traditionally, the wood cutting industry was dominated by larger companies who were able to run in-house departments to manually do their wood cutting work. Over the years, technologies began to advance and eventually computer-controlled machines took over the industry. With this came the boom in laser cutting, especially over the last decade. Specialist companies were set up who now solely focus on offering digital fabrication services, providing a high turnover of quality products in faster turnaround times. Larger businesses often outsource their work to these companies, as the most cost-effective option. This is now one of the most cost-effective methods used and as such, has become an affordable option for all businesses to access.

There’s a broad range of services that can be accessed and this includes laser cutting wood panels as well as engraving services. There are many materials that can be used for laser cutting wood panels and the versatility of not only the wood but of the laser cutting technique itself, opens the doors of possibilities.

Let’s start with the basics and have a look at what laser cutting entails.

Laser Cutting – the Basics

While laser cutting may seem like a pretty self-explanatory term, there’s a lot more to the technique than some might imagine. The process starts when expert technicians receive a vector-based file. These are often in the formats .dwg, .dxf, .eps or .ai. PDF files can also be used but only if a vector-drawn design can be exported from the file. 3D files are also an option in laser cutting, but if this is the case for your project, it’s advisable to speak to our specialist laser cutting team first who can help you with these. Our specialist technicians will then load the vector-based file onto a computer connected to the laser cutter. This will read the drawing in the design file and produce a series of coordinates for the laser cutter to cut the material with.

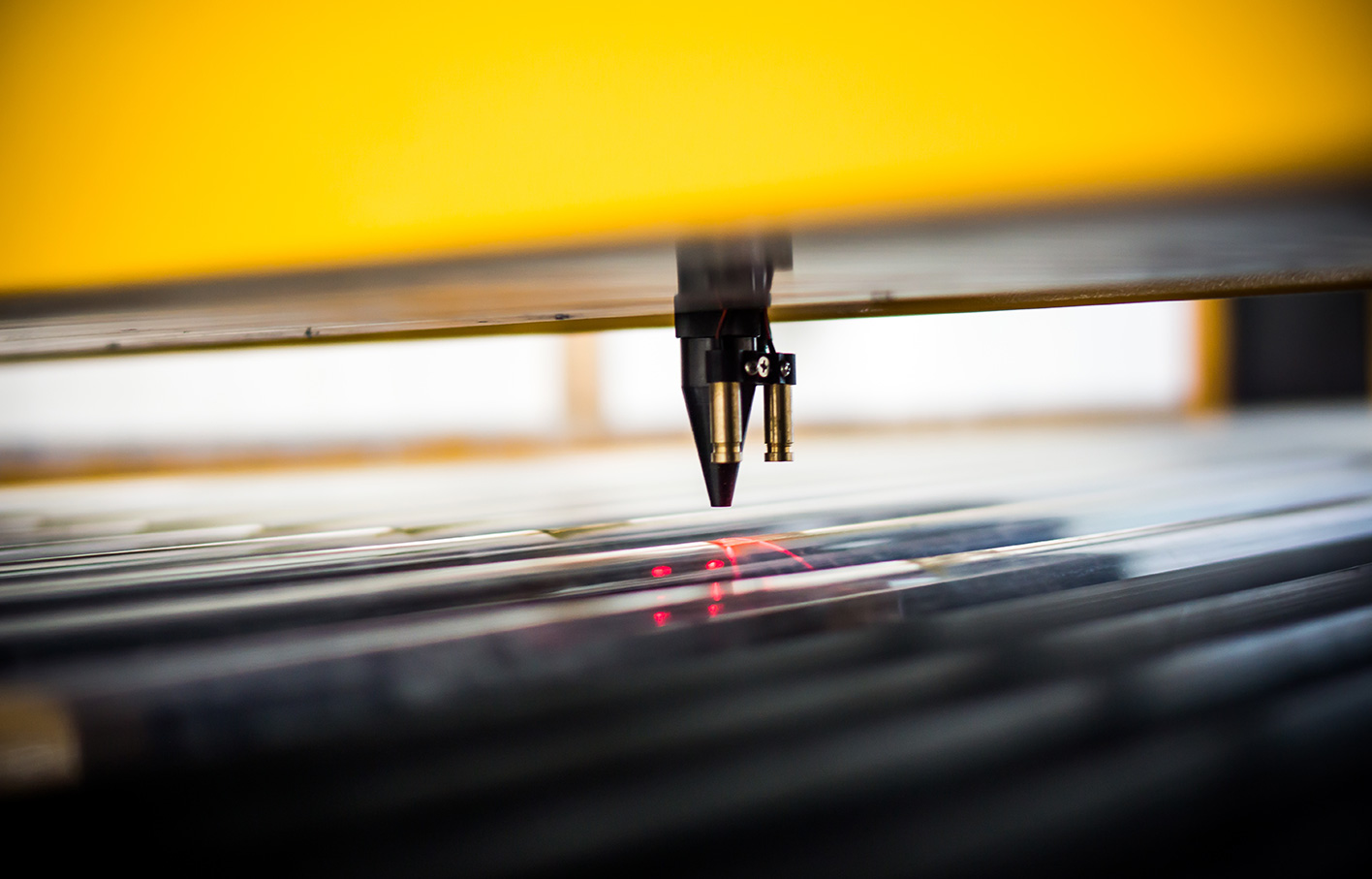

From here on in it’s a largely automated process with little need for any manual intervention. The laser travels down an encased tube, reflecting off a series of mirrors, and being angled onto the material to start cutting. The beam is produced by a powerful blub which can control the intensity of the beam to allow the right cutting techniques to be produced. Lower settings are used for processes such as etching into wood and higher settings are needed for cutting through more solid materials.

The laser cutter easily cuts the material in a short timeframe and can then move onto the next material that’s programmed for it to start cutting.

Laser Cutting Possibilities

There is a vast range of materials that can be cut on laser cutting machines. The two most common services accessed are laser cutting and laser engraving services.

The choices of materials for both services include:

- Engraving: wood, glass and acrylic

- Cutting: sheet materials, softwood, solid timbers, plastics, acrylic, laminates, card, foam, soft leather

Wood options are present on both the cutting and engraving lists, proving what a versatile material it can be. Laser cut wood panels is one of the most popular services chosen here at Aldworth James & Bond.

Laser Cut Wood Panels

Laser cut wood panels covers a wide range of wood material options.

It includes:

- Sheet materials such as MDF and plywood

- Solid timber panels e.g. oak panels

- Laminated materials

- Veneers

It also includes pattern cutting for things like wood screens or inlays.

Plywood and MDF are two of the most popular choices for laser cut wood panels. Plywood is popular due to it being such a strong but lightweight material and being more affordable than solid timber. Solid timber is often chosen for a being a much thicker and solid type of panel but is more expensive. MDF is a popular choice for wood panels due to its versatility such as different colours and thicknesses. Certain types of MDF can also be bendy and others can be incredibly moisture resistant. MDF has a smooth finish so can be painted, or brands such as Valchromat already come in a range of colours. There is a whole range of options for laser cut wood materials and these are just a few.

Benefits of Laser Cut Wood Panels

There are many benefits to laser cutting wood panels, some of which are listed below.

Laser cut wood panels are of the highest quality. The small head of the laser ensures the cut never exceeds that of the width of the laser beam, allowing for very accurate a precise finish. The laser cut itself produces a high quality and smooth cut. The automated process, taking coordinates from a design file, allows for many identical copies of the same wood panels to be produced, in terms of their cut. This is essential for a professional design and when precision is required for a fabrication project. The finished cut is about as close to the original design file as it ever could be.

Laser cutting wood panels is an incredibly accurate way of producing them. Not only can replicate cutting be produced on each wood sheet to be cut, but the method used eliminates possibilities of damage. Unlike other methods that use tool bits, there’s no wobble during the cutting process, as no physical part of the machine cutter actually touches the material. The laser burns through the material rather than physically cutting it. There’s no requirement to hold down the material that’s laying on the machine bed and with this comes minimal opportunities for the material to be damaged by the machines in any way. There’s also no chance of the laser being worn or depleting in quality as it’s not worn down like tool bits are through continual use. This means that each time the laser is used, it cuts as accurately as the first time.

Laser cutting works by burning through the wood, which produces minimal dust. This means that the clean up needed is far less than is required for CNC (computer numerical control) methods that use tool bits to cut the wood. This saves time, making the process as efficient as it possibly can be. There is also very little chance of mistakes happening due to its automated nature and the machines adapt to any alternations through the few clicks of a button.

Laser cutting is one of the most cost-effective ways to create wood panels. The automated process means that the cutting is done as quick and as efficiently as it possibly could be. These fast turnaround times have led to large turnovers of cut materials being produced in a short space of time. The minimal manual input during the process ensures you are not paying for large amounts of manual labour hours. As a result, these specialist services have become affordable for most businesses. Thousands of larger companies have recognised how cost-effective laser cutting has become and are therefore choosing to outsource their work to specialist laser cutting companies. Smaller companies, designers, makers and individuals can also finally access the services as a cost-effective way of cutting materials.

- Your Project – How Can We Help?

If you need help with a laser cut wood panel project, you need a company with the expertise and experience to create a high quality product with a fast turnaround time. At Aldworth James & Bond, we can provide you with just that. We are a specialist design & fabrication company who can work with you on any size or type or project and have everything you would need to complete a successful laser cut wood panels project.

We have a range of digital fabrication equipment, which includes CNC and laser cutting machines. Our laser cutters have a bed of 2440 x 1220mm which is the same size as a standard wood sheet— 8ft by 4ft. We can laser cut from A4 size and up to the standard sheet size. We are therefore more than equipped to take on the size of your laser cutting projects.

Our Team:

Our multidisciplinary team is made up of experts, all with years of experience in the design and manufacturing fields, and always happy to help! Our team includes designers, project managers, operators and technicians, who will all manage your wood cutting project from start to finish. We also provide a pre-cutting advice service and we would recommend you use the knowledge of our expert team to ensure you are using the most suitable technique and material for your project. This prevents any mistakes from occurring further down the line and ensures you are making the right choices for your project.

Our Experience:

We have all the experience required to ensure your laser cutting project is a success. We have years of experience in this field which means we have all the expert knowledge required to create the highest quality products in fast turnaround times. Our pre-cutting advice can be accessed at any time during the planning stages and some of the help we can provide using our expert knowledge includes:

- Cutting methods and overlaps in methods such as CNC

- Material options

- Material ordering

- Specialist wood panel cutting advice

- Lead times

- Design file solutions, including 3D file advice

- Quotes

- Delivery

Details about the cutting process, including nesting (’laying up’) your design on a sheet to ensure you’re using the maximum amount of material possible and there’s minimum wastage

Our Service:

We pride ourselves at Aldworth James & Bond on putting customer service at the heart of what we do. We strive to create the smoothest and most professional service from the minute you make the first contact with us to the safe delivery of your finished items. Our central London (Zone 2) location means we’re in a great location for customers to access our services and we have a fleet of vehicles which can deliver nationally to anywhere in the UK. The services we offer includes:

- A pre-cutting advice service for all your project requirements including any help with design solutions, as listed above

- A team of experts at your service, including a project manager who will manage your project through the stages of the process

- A high quality laser cutting service managed by expert technicians

- A fast service in which you will be kept informed of lead times

- A collection or delivery service meeting your requirements. Your items will be packaged up and labelled, allowing you to keep track of all your finished products

- Fast costings

- An easy payment system

If you have a wood panel cutting project, our experts would love to hear from you.

Summary

Laser cut wood panels were traditionally cut using hand held tools. However, technologies have now advanced to allow cost-effective laser cutting services to be at the helm of the design and manufacturing industry, with its popularity rising. Wood panels can be laser cut from a range of materials, giving you a greater choice about what you want to create. The high quality finish and the fast turnaround times have made this cost-effective service popular for larger companies to outsource to and smaller companies to finally be able to afford.

Aldworth James & Bond are a specialist laser cutting company who are more than equipped to manage your laser cut wood panels project. We have a team of expert technicians who have years of experience in the design and manufacturing industries. We have all the knowledge needed to make this a smooth and easy process for you, however large or small your requirements. We create high quality products in fast turnaround times and can deliver to any UK location.

Laser Cut Wood Panels – Next Steps

If you have a wood panel project, the next step is to get in touch! Whether you just need an informal chat with one of our team, a quote, specialist advice, or to book your laser cutting project in with us, contact us on one of the three simple methods below.