Traditionally, larger companies had their own in-house departments who carried out any wood cutting services that were required. This involved manual methods such as using hand-held tools and it was a more time consuming method than modern cutting techniques. Being such a costly service meant that smaller businesses were unable to access such services, as they were not affordable or even available.

As technologies advanced, computer-controlled machine cutting entered the industry, which included laser cutting techniques. The introduction of laser cutting created a high quality finish and fast turnarounds previously unseen by manual methods. With this came the birth of specialist companies who focus solely on offering laser cutting services. The high turnover of quality products in such a short timeframe means that these companies now offer a cost-effective service, available to all. Larger companies began to outsource to these companies and smaller businesses, designers and makers now have an affordable option. There is a wide range of materials that can be used in laser cutting, with laser cut wood being one of the most popular picks.

Let’s start with the basics and look at what’s involved in the laser cutting process.

Laser Cutting – What’s Involved?

Laser cutting is a largely automated process that involves a design file, a computer, and a set of coordinates. To start the process, an expert technician will need a design file containing the vector-based design, image or shape that needs to be cut into the material. This usually involves a design file in the format of .ai, .eps, .dwg, or .dxf. PDFs can be used if there is a vector-based image that can be exported from it. 3D designs are also a possibility, but it’s recommended you speak to your laser cutting company about these.

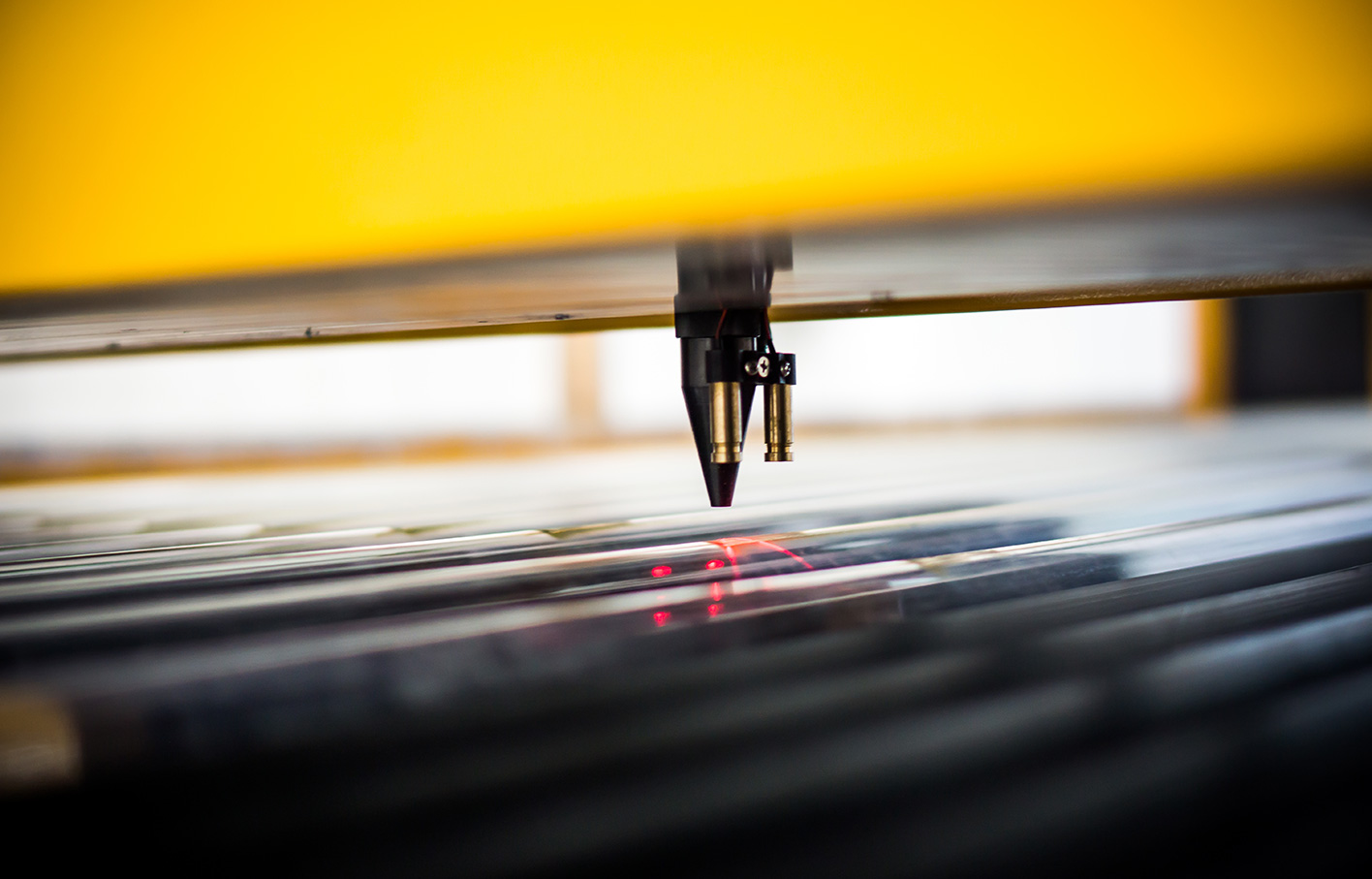

Vector-based files are used so the laser cutter can translate the file into a language it understands. This takes the form of a set of coordinates which need to be cut or engraved into the material on the machine bed. Once the file has been correctly loaded by the technician, the process is automated. A powerful laser is sent down an encased tube which reflects off a series of mirrors. The laser is then angled onto the material and the cutting begins.

Laser cutting produces an accurate replica of the original design file. Its coordinates will be the same as the vector exported from the file and the cutting does not exceed the width of the laser beam. This ensures an accurate and high quality finish.

Laser Cutting Possibilities

Two of the main services used in laser cutting are a cutting service and an engraving service. The powerful bulbs in the machines control the intensity of the laser to ensure the machine is set to the right cut for the job. Lower settings are used for things like laser-etching wood and higher ones would be used for cutting thicker materials.

Common types of cutting material include:

- Plywood

- MDF (including Valchromat)

- Oak panels

- Softwood

- Acrylic

- Plastics

- All laminate types

- Foam, card, soft leather

Common types of engraving material include:

As you can see, types of wood appear on both the lists for cutting and engraving, meaning that laser cut wood is quite a versatile concept.

Laser Cut Wood

Laser cut wood is popular because the effects you can create are so varied. Engraving services can etch intricate designs and detail into wood and there many options for cutting services. Here are a few of the most popular options:

Plywood - This is the most popular sheet materials we see used in laser cutting and manufacture. Its strong but lightweight nature makes it versatile, as well as the fact it comes in a range of thicknesses. It’s also a much more affordable option than solid timber. With laser cut wood projects it’s usually sensible to go by the rule that the thicker the material, the higher the price. WISA is one of the most chosen types of softwood ply and comes in either birch or spruce.

MDF - This is also a popular sheet material used for laser cutting. It’s incredibly versatile and its smooth finish means that it’s perfect for painting. Brands such as Valchromat already come in a variety of colours. We also supply moisture-resistant MDF.

Wood Panels – Laser cut wood panels can be created with a variety of materials. As well as sheet materials discussed above (plywood and MDF), options include solid timber panels (such as oak panels), laminated materials, and veneers. Laser cutting can also include pattern cutting for inlays and wood screens.

Engraving – Wood is one of the most popular choices for engraving. This is because you can achieve a great deal of detail and intricate designs etched into the wood. Popular things to engrave include logos, text and photos which has given businesses more ways to advertise their brand and display their products. The high quality finishes give products the professional touch.

Benefits of Laser Cut Wood

Laser cutting is one of the most versatile techniques of cutting wood. There are many options when is comes to laser cut wood, including cutting methods and engraving. Laser cutting projects vary from one to the next but pretty much any design from a vector-based design file can be reproduced on the wood. The intricacy of laser cutting has enabled a much broader list of cutting options than other machine techniques that use tool bits. These include high quality finishes and features such as smooth curves, sharp corners and angles, tiny screw holes and complex lacy patterns. This coupled with the fact there are so many types of wood you can choose from, the possibilities are endless.

One of the best aspects of laser cutting wood is the detailed and intricate designs that can be achieved if required by a project. This is due to the small head of the laser cutter, meaning that the cut never exceeds that of the laser beam. This allows for incredibly detailed work including engraving possibilities. Popular engraving options include text, logos and photos which are developing the way companies choose to advertise their brand and display products. Laser cutting can be done for almost any drawing that is created in a vector-based design file.

The small head of the laser means that the effects created by laser cutting is sharper than other techniques and creates a professional and high quality finish. The laser burns through the material rather than cutting it, meaning that minimal dust is produced and the clean up is significantly lower than those techniques that use tool bits to cut the material. There’s also minimal risk of damage to the material. Taking wood for example, there’s no need to fix the wood down as no physical part of the laser cutter comes into contact with it and there’s no wobble as the laser burns through the wood to cut it. This ensures the risk of damage to the material is extremely low and increases the reliability of this method. There’s also the benefit that unlike tools, which become worn down due to continuous use, a laser stays as sharp as the first time it’s used. This allows for a high quality finish every time, as if the machine was brand new.

This process has become largely automated, resulting in fewer man hours needed to complete a job and minimal manual intervention is required. The efficient process has also allowed a high turnover of materials to be cut within a short amount of time. Various materials can be cut during one operation and several jobs can be programmed in to be carried out in succession, without manual interference. This is particularly handy when producing multiple copies of the same product. Any alterations are immediately implemented by the machines and the changes can be programmed in with just a few clicks of a button. This ensures the process is as efficient as possible. The creation of high quality, laser cut wood items in such a fast turnaround has ensured laser cutting services are as cost-effective as they possibly could be. This has opened up affordable options for smaller businesses and has become a popular choice for outsourcing for larger companies.

We Can Help You

Whatever stage of your laser cutting project you are at, you need to think about what your requirements are and the type of laser cutting company you want to use. They should be reliable, experienced, communicate with you at all stages of the process and produce high quality items in fast turnaround times. We believe that at Aldworth James & Bond, we are just that. Putting customer service at the heart of what we do, we strive to make your experience as smooth as possible from start to end, and your project’s a complete success.

We are equipped with the latest technologies in digital fabrication and this includes laser and CNC (computer numerical control) cutting machines. Our laser cutters have a bed size of 2440 x 1220mm which is the standard sheet size for wood. We can cut any size from A4. We have everything you need for your laser cut wood project. This includes a dedicated team of experts such as designers, operators, technicians and project managers who look after all our laser cut wood projects.

Examples of laser cut wood projects we have experience of include:

- Modelling projects

- Construction projects

- Signage jobs

- Complex furniture projects

These are just a few examples of the laser cut wood jobs we have worked on, but we can help you whatever the type, material and size of the job.

Our team can also offer pre-cutting advice which is particularly recommended if you are unsure about any aspect of your project. Types of pre-cutting advice we can offer you include material choices, cutting methods, design file solutions, lead times, quote and costings, material ordering, delivery options and scheduling your job in with our technicians.

Our expert laser cutting service puts our customers at the heart of what we do. We can help you in any way you need and can take on any type or size of project. We are based in a fantastic London location (Zone 2) and have a fleet of vehicles that can deliver your finished items straight to your door in any UK location. We always package and label up your items to ensure you can keep track of which jobs we have completed for you. Also we’re happy to offer a collection service if that is more convenient for you.

If you have a laser cut wood project or any other material that needs cutting, we would love to hear from you.

Summary

The design and manufacturing industry has been revolutionised by technology. Computer-controlled machines such as laser cutters are now one of the most cost-effective methods of cutting and engraving materials. The process is fast, reliable, cost-efficient and can produce high quality and detailed designs.

Laser cut wood has become a popular option when accessing laser cutting services. Wood is incredibly versatile and can not only be cut but also can be engraved. There’s a wide variety of woods used in these services and a large number of effects that can be created, including intricate designs and wood-etching.

Aldworth James & Bond are specialist laser cutters situated in London (Zone 2). We have a team of experts on hand, including experienced designers and technicians who have all the knowledge and expertise to successfully manage your project from the initial contact through to the delivery of your items. Collection services are available, but we can also deliver to anywhere in the UK.

We would love to hear from you.

Laser Cut Wood Projects – Next Steps

If you have a laser cutting project you need help with, please get in touch. One of our team can have an informal chat with you and see what your requirements are. Whether it’s a quote, an informal chat, detailed pre-cutting advice or to schedule your cutting job in with us, we are happy to help.

Contacting us is easy and there are three simple ways to do it: