Material cutting was traditionally carried out by in-house departments. This was mostly done by manual methods, using hand held tools, which was time consuming and labour intensive. As new technologies entered the design and manufacturing industry, computer-controlled machines introduced new cost-effective methods for cutting materials, and this included a boom in laser cutting techniques. Specialist companies developed, finally giving individuals and smaller companies a chance to access such services, and larger companies began to outsource their work once they realised this was a more cost-effective way of doing things.

One of the fabrication methods that’s growing in popularity is laser cutting. It’s a versatile method, creating high quality finishes and with intricate designs possible, it’s also a popular choice for engraving projects as well as cutting. Plywood is one of the most popular choices of material for this method.

Let’s have a look at what laser cutting really entails.

What Is Laser Cutting?

Laser cutting does what it says on the tin, basically meaning that materials are cut via a focused laser beam. It’s pretty self-explanatory. However, the process is actually more complex than you would think and what not many people realise, is that it’s a largely automated process.

Before the laser cutting process can begin, technicians require a design file. This should be a vector-based file in a .dxf, .dwg, .ai, or .eps format. PDF files can also be accepted, as long as a vector can be exported from it. 3D files can also be used, but it’s probably wise to speak to the laser cutting team at Aldworth James & Bond about these. The files need to be in a vector-based format so that the laser cutter’s computer can translate them into a set of coordinates for cutting the material with.

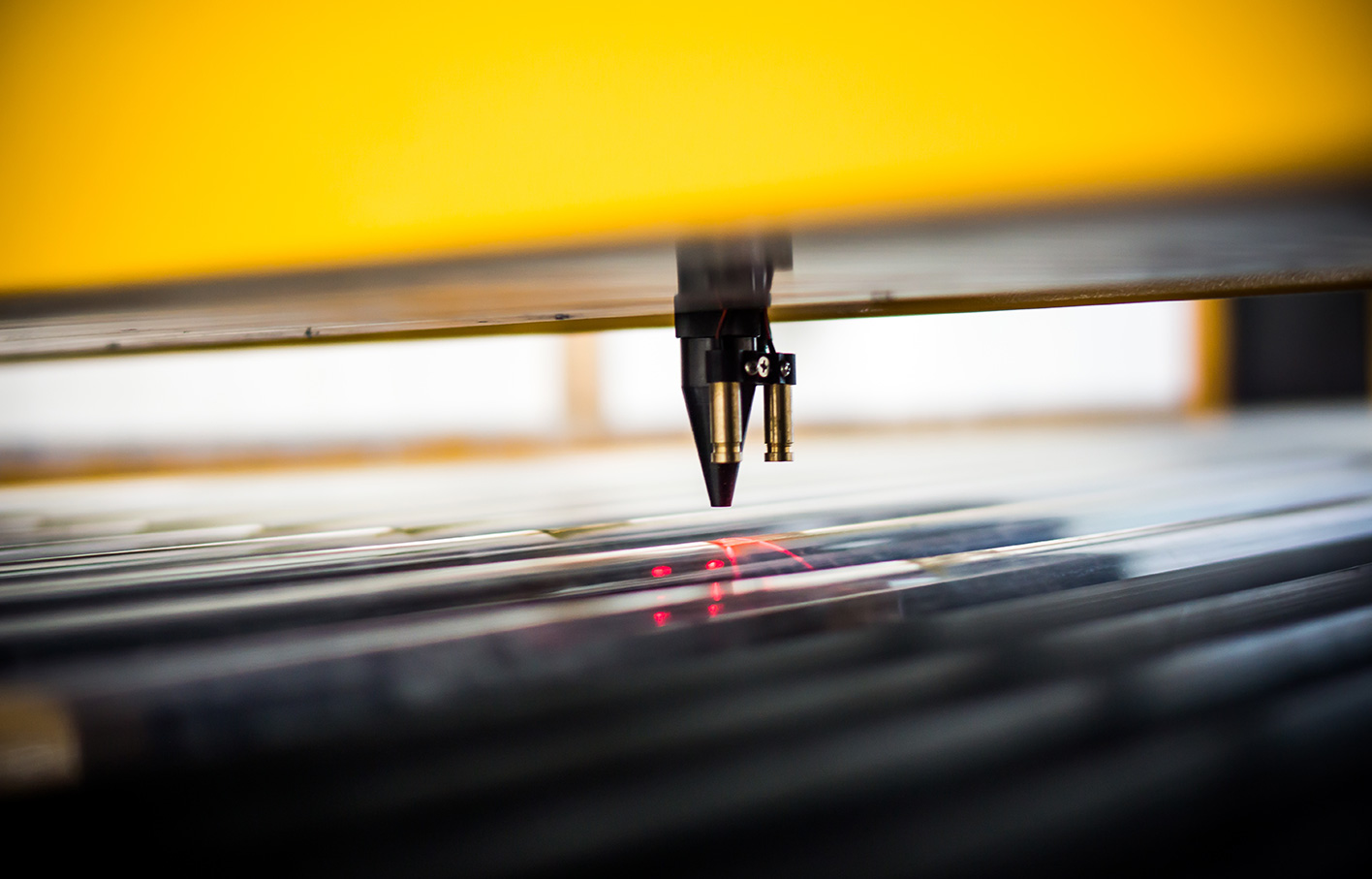

The automated process begins when the laser is sent down an encased tube, reflecting off a series of mirrors, to then be angled onto the material and start cutting precisely as the design file has stated. The machine does the hard work, meaning that the human interaction needed is minimal. The laser is produced by a powerful bulb, but the machine can adjust the intensity of the laser to get the right cut it needs for the material.

The finished effect is of a very high quality.

What Can Lasers Cut?

Laser cutting is mainly used for cutting and engraving services.

Materials that can be cut include:

- Plywood

- MDF (including brands such as Valchromat)

- Moisture-resistant MDF

- Softwood

- Solid timber panels and worktops

- Plastics & Acrylic

- Laminates

- Card

- Foam

- Soft leather

Materials that can be engraved include:

Laser Cut Plywood

Plywood is the most popular and most frequently used sheet material used in manufacturing and therefore one of the mot popular to laser cut. Its popularity is largely down to it’s strong but lightweight nature and the fact it’s cheaper than most solid timbers.

It comes in various grades (including softwood face, hardwood face and marine grade) and there’s a range of thicknesses available. As with most laser cutting jobs, the thicker the plywood, the more expensive the job. One of the most popular plywood brands is WISA, coming in either birch or spruce. The standard sheet size is 2440mm x 1220mm, which is the same size as the material beds on our laser cutting machines.

Laser cut plywood is a great option if you are looking for a cost-effective but reliable material option.

Benefits of Laser Cutting Plywood

There are many benefits of using plywood as a material, but there are also benefits of using laser cutting techniques to cut plywood once you have selected it as your material of choice for a project. Some of the main reasons to laser cut plywood are:

Flexibility

There are so many things you can do with plywood if you choose to have it laser cut. Laser cutting can cut the plywood using almost anything drawn in a vector-based design file. This includes complex lace designs, sharp angles, smooth curves and small screw holes.

These types of sharp cuts are just not possible with traditional techniques or methods that use tools bits. The cutting is a lot more intricate meaning that a sharper finish is possible.

Quality

Much of the high quality produced by laser cutting is down to the small cutting head used by the laser. CNC (computer numerical control) machines that use tool bits have a much larger head and therefore cannot produce quite the same sharp finish that laser cutting does, although still produce high quality effects. The clean up is also minimal. The laser works by burning through the material to cut it, so you don’t get as much dust produced as you do with CNC methods.

Accuracy and precision are also maximised by the intricate cutting that takes place. The automated process means that the laser cut plywood will be about as close to the original design file as it ever will be. This is particularly useful if you’re making multiples of the same item, as this will ensure a professional finish for your product.

Reliability

Firstly, there are minimal risks to the plywood being cut via laser cutting. No moving part will actually be touching the plywood and it does not need to be held down. This is because there’s no wobble during the cutting process. This largely eliminates the risk of the plywood being damaged. The laser does not wear over time like tool bits do with continuous use. The laser quality remains the same, however many times you use it.

There are also very few mistakes with this method of cutting. Any changes or modifications can be made at the click of a few buttons. The laser cutters adapt to these changes without issue, meaning that alterations can be made with minimal disruption to the process.

Speed

The automated nature of the laser cutting process has resulted in a vastly reduced time for the job to be completed. Once the design file has been correctly uploaded to the laser cutter’s computer software, the machine works autonomously to cut the plywood by itself. This means that multiple jobs can be loaded and the machine will carry them out in sequence. This leads to a high turnover of material at any one time and therefore very quick turnaround times can be achieved. Various materials of varying thicknesses can all be cut within one operation without manual input once the cutting process begins. This is a very time efficient process that has led to the quick turnaround times now offered by laser cutting companies.

Costs

Being a largely automated process, the need for human interaction with the laser cutting process is kept to a minimum. The traditional techniques were incredibly labour intensive, with more people involved and much longer hours needed to complete a job. As a result, laser cutting is now considered a very cost-effective method of cutting materials such as plywood. Expert technicians set the jobs up using the design files and then the machines do all the cutting work. Large companies are now often choosing to outsource their work to laser cutting companies and smaller companies, designers, makers and individuals can now access the services due to their affordability. Using specialist cutting companies is one the most cost-effective methods you can choose.

How Can Aldworth James & Bond Help?

When looking for a company to carry out your plywood cutting project, you need to know you’re in safe hands. By choosing a company with the specialist skills to do the job, you know you have an experienced team to carry out your laser cutting.

At Aldworth James & Bond, we are passionate about digital cutting techniques. We have a range of equipment, including CNC and laser cutting machines. Therefore, we’re more than equipped to carry out your plywood laser cutting project. We’re happy to take on any project and our team are highly experienced in this field. Our laser cutters are fitted with a standard sheet size of 2440mm x 1220mm, allowing us to laser cut plywood up to this standard large size.

Our specialist team of technicians are the experts, all with backgrounds in design and manufacturing. No job is too big or too small and we have years of experience completing successful projects time and time again of the highest quality. Some of our most complex projects completed have been with architectural companies, designing models which are vital for their conceptualising work. We also have experience in complex furniture projects and a wide range of signage jobs. Whatever your plywood laser cutting project is, we’re happy to help.

Based in a zone 2 location in London, our fleet of vehicles can deliver to anywhere in the UK (collection is also available). We will package and label your plywood items up for you so that the process is as smooth as possible.

Pre-cutting advice available:

Our specialist technicians can offer as much advice before the laser cutting commences as you require. Whether it’s a simple cutting job or a large or complex project, we can offer you as much or as little advice as you need. The more you use our knowledge and expertise, the less chance there is for any mistakes, ensuring the process is as quick and therefore, affordable as possible. Our pre-cutting advice can cover:

- Cutting methods

- Material options and ordering

- Specialist plywood cutting advice

- Design file solutions

- 3D designs

- Turnaround times

- Quotes

- Delivery & after care

Once you’re happy with your project plan, we can schedule you in. Our expert technicians will ensure your plywood and materials are cut to the highest quality.

Our customer service promise:

Customer service is put at the heart of Aldworth James & Bond. We love what we do and we want you to find the process as smooth as possible from the initial contact right through to the delivered finished product. What we will provide you with:

- any pre-cutting advice you require

- help with design solutions

- high quality laser cutting or engraving with our specialist machines

- fast turnaround times - If we already have the material in stock, this will speed up the process ever more!

- packing and labelling of all your finished items. This allows you to keep track of all the items we’ve laser cut for you.

- fast delivery of your finished projects to any UK location

- the option of a collection service if required

- fast costing turnaround times

- an easy payment system, including credit card use

If you have a laser cut plywood project or any other material that needs cutting or engraving, we would love to hear from you.

Summary

The design and manufacturing industry was revolutionised by the introduction of technology and with that came a boom in laser cutting. It’s quick and reliable method was finally a chance for companies to access such services and produce high quality products in a cost-effective way. Laser cutting can be done for a wide range of materials, but plywood is the most popular.

Laser cut plywood is often picked as the material choice as it’s more affordable than solid timbers but remains strong yet lightweight. It’s all round benefits make it one of the most popular sheet materials to use for laser cutting.

Aldworth James & Bond are proud to offer an expert laser cut plywood service, producing high quality finishes and fast turnaround times. Our expert team has years of experience in completing such projects and we can advise and help you in any way you need. Your plywood project will be in safe hands with us and we are happy to work with you to make it as successful as it can be.

Laser Cut Plywood Projects - Next Steps

If you have a project involving plywood or any other materials, we would love to hear from you. Our expert technicians are available to speak to you about all your requirements and can offer as much pre-cutting advice as you need.

Just contact us by filling out our simple online contact form, or alternatively, you can email hello@aldworthjamesandbond.co.uk or give us a call on +44 (0)20 8269 0883.