In-house teams traditionally provided companies with material cutting solutions. This was mostly done via manual methods, using hand held tools, and taking up many man hours to complete projects. As technologies advanced, specialist companies entered the design and manufacturing industry, running their own services focusing solely on digital fabrication services. This opened the doors of these services to many more designers, makers and individuals, by providing affordable options for material cutting services. Many companies now outsource to these companies and one of the main techniques now used is laser cutting.

Laser cutting is one of the most versatile cutting techniques, with a high quality finish that is increasing its popularity. Its fast turnaround times mean that it’s an incredibly cost-effective process. MDF is one of the most popular materials chosen for laser cutting due to its affordable costs and versatility.

Let’s start with the basics and take a look at what laser cutting involves.

What’s Laser Cutting?

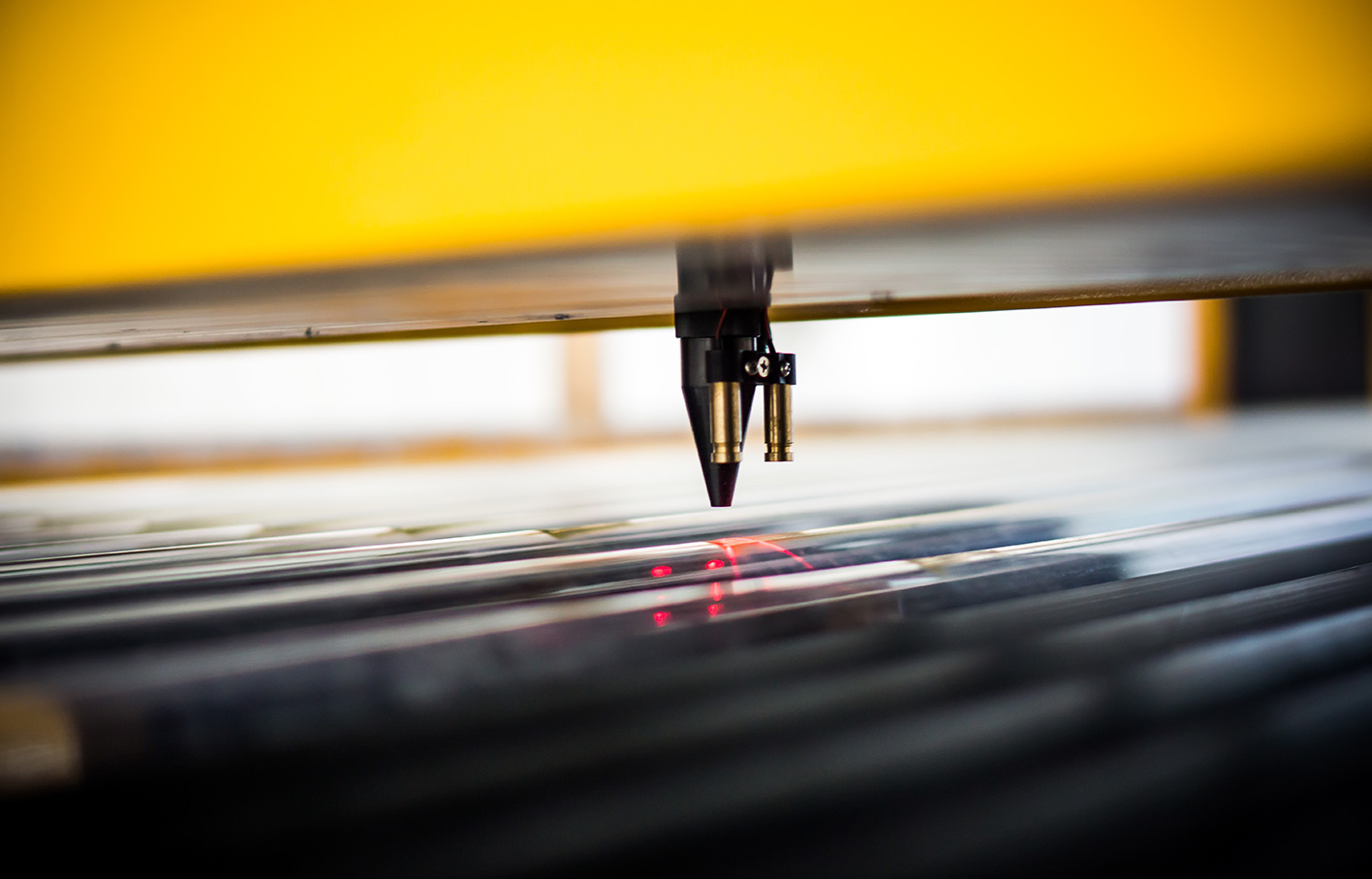

Laser cutting is a pretty self-explanatory term that does what it says on the tin. While it basically means that the material is cut via a laser, there’s a lot more to it than just that. It’s a surprisingly automated process which involves very little manual involvement once the cutting process actually begins.

Laser technicians firstly need a design file that’s in a vector-based format. These formats include .dxf, .dwg, .ai, and .eps. PDF files can also be used if a vector is able to be exported from them and 3D files can be considered as well (but speak to your laser company about these). The design files are required to be in one of these formats in order for the laser cutter’s computer to transfer the data into a language it understands – coordinates for cutting the material! The process then begins and the machine does the hard work from here onwards.

The laser is controlled by a powerful bulb and the laser cutting machines can control the intensity of this so that the cut is just right for the material being cut. The finished product has a high quality finish and the turnaround times are quick, ensuring the process is as efficient as possible.

What Materials Can Lasers Cut?

A wide variety of materials can be laser cut, and our machines can do all. Customers can choose from cutting or engraving services, depending on their requirements, and this may affect the material they choose for the job.

Laser cutting materials chosen:

- MDF

- Plywood

- Softwoods

- Solid wood panels

- Plastics

- Acrylic

- All laminates

- Softer materials e.g. soft leather, card, foam

Laser engraving materials chosen:

Laser Cut MDF

MDF is a popular sheet material, second only to plywood, chosen for laser cutting due to its versatility. It comes in a range of thicknesses and available in a moisture resistant type. It’s worth remembering that as a general rule, the thicker the material, the higher the cost of laser cutting. MDF is also great for laser cutting because it normally already comes in a standard sheet size (2440mm x 1200mm), which is perfect for our laser cutting machines.

MDF is also available in a ‘bendy’ form, which can be cut and pressed and formed in to a wide range of configurations. The brand ‘Valchromat’ is also popular, as it comes in different colours, making a change from the traditional brown MDF. Another popular brand selected is Medite. We supply most brands and types— just get in touch with one of our dedicated team to find out more.

MDF is usually cheaper than plywood so costs will be lower, it has a smooth appearance so it’s great for painting and is consistent throughout.

Benefits of Laser Cutting MDF

MDF is a popular material to use for laser cutting but why is laser cutting a popular fabrication method to use? And why is it better than CNC in some instances?

If you have an MDF cutting project, you need to bear these benefits in mind.

The laser beam is encased by a very small head on the machine. This produces a high quality finish on the end product due to the precise nature of the laser. The clean up of the laser cutting method is also minimal compared with other methods. Because the laser works by burning through the MDF, no dust is produced.

The automated nature of the process also results in a greatly accurate and precise finish which is extremely important if you are creating multiple copies of the same object. The machine is automatically programmed to produce a cut as close to the original design file as possible, meaning that you get a professional finish every time.

Laser cutting is an extremely reliable method of cutting MDF and other materials. There is no wobble when the cutting process takes place, as the material does not need holding down. No moving part of the machine ever touches the product so the risks of damage to the MDF or other materials is minimal. Lasers also never deplete in their quality. Tool bits get worn over time but with laser cutting, you can be assured the laser remains as sharp as the first use.

Few mistakes happen with laser cutting, especially if you seek the advice of a specialist laser technician team. Any alterations can be made at the click of a button and the laser cutter will adapt straight away. This ensures there is minimal disruption to the process should changes need making.

MDF is an incredibly versatile material which is why it is so popular (along with its affordability). However, laser cutting is also an incredibly versatile cutting technique, opening the way for more projects to be able to benefit from this cutting method. Laser cutting is a very accurate technique, but also can be intricate. It has the ability to replicate almost anything drawn in a vector-based file. This includes things like sharp angles, smooth curves, complex lace designs and small screw holes. These sharp finishes are not possible with traditional methods or tool bit techniques, due to the small head on the cutter resulting in cuts only going as wide as the laser beam.

Laser cutting is one of the fastest cutting methods available to companies. Because of the automated nature of the process, once the design files are correctly loaded, the machines can autonomously cut the MDF and other materials. Various materials can be loaded at any one time and the machine can cut these during one operation with no need for manual interception. This results in a time efficient process, thus leading to fast turnaround time for clients. If multiple copies are being made of the same item, the material turnover is extremely high, thus making it one of the fastest cutting methods available.

Not only is the laser cutting process mostly automated but the human involvement is limited compared with traditional methods. Before technology came into the industry, cutting methods were labour intensive and relied on many more people to get the job done. For this reason, laser cutting materials such as MDF has become one of the most cost- effective services around. This is the reason many larger companies are now outsourcing their work to specialist laser cutting companies. Not only this but individuals and smaller companies now have access to the service at affordable rates due to the cost-effective nature of the technique.

How Can We Help You?

If you have an MDF laser cutting project, you need a company who have the experts at hand to advise and carry out your job to the highest quality possible. At Aldworth James & Bond, we pride ourselves on being able to do just that. We have several cutting machines both of the CNC (computer numerical control) and laser cutting variety, so we’re more than equipped to take on your MDF cutting project.

Our laser cutting machines have a bed size of 2440 x 1220mm which is perfect for MDF as this is the standard size the sheet is supplied in. We are happy to take on any project and can talk through your options with you.

Our Experience:

Our expert team has years of experience in the design and fabrication sector meaning that your job will be in safe hands. We are the experts in this specialist field and have a proven track record of taking simple and complex projects onto success, every time. Some of our most complex projects have included working closely with architecture companies, producing architectural models for concept stage. Aldworth James & Bond have also been involved in complex furniture making projects. No job is too big or small and we have plenty of experience in handling and cutting MDF.

Our Service:

We are more than happy to work collaboratively with you on your project. Pre-cutting advice is available from our expert technicians if required. Not everyone knows exactly what they want so our team will be happy to talk your options through with you. This includes advice about material choices, the right cutting method, specialist MDF cutting advice, design file solutions (including 3D designs), costings information and lead times. We can also order in materials for you and of course, book your project in with our machines. Even if you just need a quote or informal chat with an expert, we’re here to help.

Customer service is at the heart of our company and we aim to give you the smoothest service possible. We offer fast turnaround times, packing and labelling of your items, a collection service if needed, fast costings, and an easy payment system is provided. We’re located in a central London location (in Zone 2) but with our fleet of vehicles, we can deliver to anywhere in the UK. Delivery is always fast and on schedule.

If you have an MDF cutting project or require any other material cutting or engraving services, Aldworth James & Bond is more than happy to assist.

Summary

The design and manufacturing sector underwent a revolution over the past few decades. Where traditional manual methods had previously been used to cut materials, technologies advanced to allow computer-controlled machines to take over. Laser cutting is now one of the most cost-effective methods used and specialist companies have opened up the doors for companies previous struggling to afford such services. Many larger companies now outsource their work to these companies, in which experts deal with laser cutting projects day in, day out.

Laser cut MDF is one of the most popular options for laser cutting. This sheet material is incredibly versatile, largely being chosen due to it being an affordable and cost-effective material to use. One of its greatest qualities is having a smooth finish which is great if you want it painted. MDF can already come in various colours, with Valchromat a popular brand of choice for this reason.

Aldworth James & Bond provides a high quality laser cut MDF service, offering fast turnaround times and great customer service. Our experts have years of experience in this field and can offer you as much advice as you need with your project before the laser cutting process starts. Delivering to anywhere in the UK, our prime London locations means that we’re in a great location.

Laser Cut MDF Projects - Next Steps

If you have an MDF project or would like to speak to one of our expert team about material choices, have an informal chat, or for any other advice you may need, we would love to hear from you.

Contact us by one of these three easy methods: