Traditionally, larger companies ran their own in-house material cutting services. This involved manual cutting techniques, often using hand-held tools, which is a more time consuming and less accurate method than modern techniques. In the design and manufacturing industry, computer-controlled machines were introduced over time, transforming the industry forever. Advances in technologies resulted in laser cutting techniques becoming one of the most cost-effective methods around today.

Specialist companies now focus solely on offering laser cutting services and this includes offering laser cut engraving services for a range of materials. These cost-effective methods produce high quality products in fast turnaround times. There’s a wide variety of materials that can be used on our laser cutting machines. Larger companies now choose to outsource to these specialist companies as the most cost-effective way to have their materials cut or engraved. Smaller companies and individuals now finally have an affordable service they can access.

Let’s take a close look at what laser cutting is and how it’s used.

What Is Laser Cutting & Engraving?

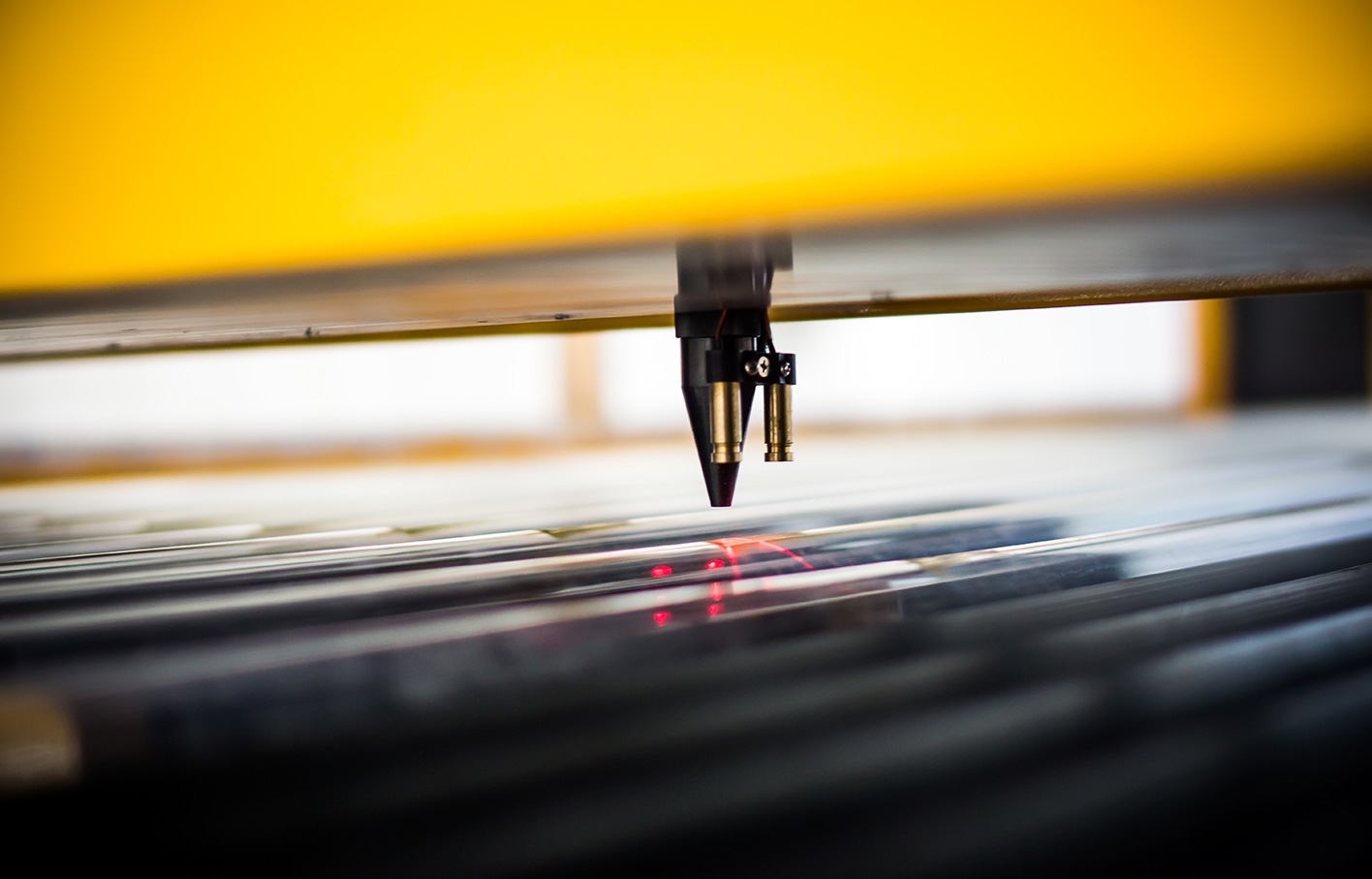

Laser cutting and engraving are self-explanatory terms in that cutting or engraving is carried out via a laser. The laser burns through the chosen material rather than physically cutting it. The actual process is a little more complex than people may realise and is largely automated.

The process begins with a laser cutting technician receiving a design file in a vector-based format. This is usually a .eps, .dwg, .ai, or .dxf design file. PDF files can be used as long as they are vector-based. 3D design files are also an option, but it’s recommended you seek advice from our team here at Aldworth James & Bond about these. Vector-based design files are needed so that the laser cutter’s computer can translate the image into a language it understands – coordinates for cutting!

Once the design file has been correctly loaded, the automated process can start. The material lays on the machine bed and a powerful bulb controls the intensity and fire settings of the laser. Lower settings will be used for laser cut engraving and higher ones will be used for cutting more solid materials. The laser travels down an encased tube, reflecting across a sequence of mirrors and then angled down onto the material to start etching or cutting.

The laser follows the coordinates read from the design file, which creates an accurate replica of the original file.

Laser Cutting Possibilities

The two main services chosen in laser cutting are complete cutting projects and engraving services.

Laser cutting can be done for materials such as plywood, MDF, wood panels, softwood, plastics, acrylic, all laminate types and soft materials such as soft leather, foam and card.

However, laser cut engraving services are now growing in popularity due to the high quality and accurate finishes they produce with fast turnaround times. There are a wide range of materials that can be used for laser cut engraving and these include:

Engraving possibilities are increasing with laser cutting. Popular choices of features that can be engraved include:

This not only creates a professional look on products but is changing the way companies promote their brands and display their products. The intricate nature of laser cut engraving allows such features to be etched onto your material of choice and these designs can be incredibly intricate in nature.

Benefits of Laser Cut Engraving

There are many benefits of using laser cutting services for the purpose of engraving materials and here are just some of them.

One of the main benefits of laser cut engraving is that the finished effect is of a very high quality. This ensures your product or component has the highest professional look possible. The small head of the laser ensures that the cutting or engraving never exceeds the width of the laser. This leads to incredible accurate engraving that’s as close to the original design file as possible. Having the process automated via coordinates read by a computer also means that you can create multiple replicate items in quick succession or place the same order again, knowing you will receive the same product each time. This is also important for a professional finish.

There are many possibilities with laser cut engraving and also many materials that it can be performed on. Wood is one of the more popular choices for engraving, for example. This is because you can achieve accurate detail and intricate designs etched into the wood. As previously mentioned, typical engraving options include text, photos and logos but the possibilities are endless. You can reproduce almost any drawing from a vector-based design file. Many choose to combine laser cutting and engraving services. Laser cutting services are also versatile and the options you can achieve are far broader than if you were using other machine cutters that use drill bits. These include features such as sharp corners, smooth curves, small screw holes and complicated patterns.

Laser cut engraving is one of the most reliable methods you can choose. There’s minimal clean up as the laser beam burns through the material rather than physically cutting it, producing minimal dust. There’s also minimal risk of any damage being done to the material. The material does not need strapping the machine bed as there is no wobble as the laser begins to cut and no physical part of the machine cutter ever touches the material on the machine bed. There’s also the benefit of the laser always cutting the material as if it were brand new. Unlike tool bits, lasers do not wear down over time, meaning that they remain as sharp as the first use. The process is also designed in a way to ensure there will be no errors due to the automated nature of the process.

Laser cut engraving is one of the fastest methods you can opt for. Once the design file has been loaded, the automated process ensures the job is completed as efficiently as possible. Multiple jobs can be loaded at any one time so that they can be done in succession without manual intervention. Various materials can also be loaded during one operation which also makes for an efficient process. Even if there are any changes to be made, these are done in the few clicks of a button and the machines adapts to the alterations immediately.

Laser cut engraving has become one of the most cost-effective methods around. This basically means that a high turnover of high quality goods is being produced in the shortest amount of time possible. The automated nature of the process also means long hours are not required for the job and there is minimal manual intervention other than the technician managing the design file. The laser cutters do the hard work after this. Being such an efficient and cost-effective method has led to many larger companies outsourcing to specialist laser cutting companies and smaller businesses and individuals now have affordable access to such services.

Your Project – How Can We Help?

When looking for a company to carry out your laser cut engraving project, you need a company who have the right expertise, right experience and right equipment to carry out your job to the highest quality. We, at Aldworth James & Bond, firmly believe we provide this service, putting customers at the heart of what we do and having the best team possible to manage your project.

We provide digital fabrication services and have several cutting machines. Our laser cutters have a bed of 2440 x 1220mm which is the standard sheet size for most materials. We have a dedicated team on hand from the start including designers, project managers, operators and technicians.

Our Experts:

Our team are all from design and manufacturing backgrounds and have years of experience in this industry. Being a specialist company means that we have the experience needed to take on any size or type of project and use our knowledge and sound processes to make it a success, every time. We love what we do and are happy to do simple jobs right up to more complex fabrication projects.

Our Knowledge:

Having such an expert team means that we are happy for work collaboratively on your project in any way that you need us to. We know from experience that every project is unique and each customer may have different requirements. We are therefore happy to work as closely on the project with you as you need. We provide a pre-cutting service which is highly recommended if you are unsure of any aspect of the service or what you need. Topics we can cover includes:

- Material choices

- Material ordering

- Cutting methods

- Specialist laser cut engraving advice

- Design file solutions

- Help with 3D files

- Information about the cutting process

- Lead times

- Quotes

- Delivery and collection information

- Scheduling in your job with our technicians

Our Service:

Customer service is at the heart of Aldworth James & Bond. It’s important to us that we deliver a fantastic service, creating high quality products with fast turnaround times, delivering the most cost-effective service we can. We also believe the process should be as easy and smooth for you as it can be. From the initial contact right through to the delivery of your finished goods, we are dedicated to giving the best customer service possible. The following great services are available:

- High quality laser cutting and engraving services

- We’ll take on any type or size of job

- Pre-cutting advice is available about anything you are not sure about or need clarification on

- All the design file help you need to make your project a success

- Fast turnaround times – you’ll always know lead times in advance and if the material is already in stock, we can schedule your job in even quicker

- The packing and labelling of all your finished items so that you can keep track of what’s been completed

- Speedy delivery of all your items, or a collection service is available if required

- Fast turnarounds for any costings and quotes

- An easy payment system is provided, including credit card payments

We are based in an excellent location in London (zone 2). We are easily accessible and close to public transport. Collection services are available, but we also have a fleet of vehicles including a Luton van with a tail lift. We will deliver your goods to anywhere in the UK.

If you have a laser cut engraving project or any other type of cutting project, get in touch today!

Summary

The design and fabrication sector has been revolutionised by technology over the years. Machine-controlled cutting has become the most cost-efficient method of choice and this includes the use of laser cutting services. Specialist laser cutting companies offer affordable options to all by producing a high turnover of high quality goods in a short amount of time.

Laser cutting services do not just include cutting. Laser cut engraving is growing in popularity due to its professional and polished finishes. It can be completed on a range of materials and popular etching choices include logos, photos and text. The accurate nature of laser cut engraving opens the doors of possibilities with intricate designs and detailed patterns easily achievable.

Aldworth James & Bond is a specialist design & fabrication company who specialise in laser engraving services for a number of materials. We have an expert team of experienced technicians, project managers, operators and designers who will guide you through the process and give you whatever help you need. Your finished items will be packaged and delivered to anywhere in the UK.

Laser Cut Engraving – Next Steps

If you have a laser cut engraving project, we would love to hear from you. Whatever stage of the project you are at, speak to one of our team who can help you move forward with the project.

You can contact us via one of these three easy methods: